OSHA workplace safety inspections are comprehensive evaluations by the Occupational Safety and Health Administration to ensure work environment health and safety standards. Key focuses include hazard identification, employer regulation adherence, and worker safety enhancement through meticulous reviews of training records, PPE availability, and SDS compliance. Non-compliance with SDS requirements can lead to fines and risks, making robust hazard assessment protocols crucial. Effective follow-up action plans, strategic goal setting, regular review meetings, and progress tracking are vital for continuous improvement in OSHA workplace safety inspections and hazard assessment protocols.

“In the realm of industrial safety, understanding OSHA workplace safety inspections is paramount. This comprehensive overview delves into the intricacies of these inspections and subsequent hazard assessment protocols, crucial for identifying and mitigating risks effectively. With safety data sheet (SDS) compliance as a cornerstone, this article explores strategies for crafting robust audit follow-up action plans, fostering continuous improvement. Furthermore, it presents best practices for implementing and monitoring follow-up actions, ensuring adherence to OSHA standards.”

- Understanding OSHA Workplace Safety Inspections: A Comprehensive Overview

- Hazard Assessment Protocols: Identifying and Mitigating Risks Effectively

- Safety Data Sheet (SDS) Compliance: Ensuring Proper Communication of Hazards

- Crafting Effective Audit Follow-Up Action Plans: Strategies for Continuous Improvement

- Best Practices for Implementing and Monitoring Follow-Up Actions

Understanding OSHA Workplace Safety Inspections: A Comprehensive Overview

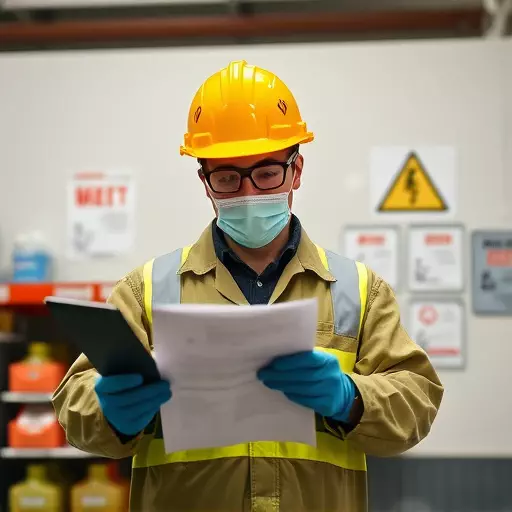

OSHA workplace safety inspections are crucial processes designed to ensure compliance with health and safety standards in the workforce. These inspections, conducted by the Occupational Safety and Health Administration (OSHA), involve a thorough evaluation of work environments for potential hazards. The primary goal is to identify risks, ensure employer adherence to regulations, and promote worker safety. During these visits, inspectors scrutinize various aspects including hazard assessment protocols, training records, personal protective equipment (PPE) availability, and safety data sheet (SDS) compliance.

By evaluating these elements, OSHA can pinpoint areas where businesses are falling short in protecting their employees. The resulting follow-up actions often involve creating or updating safety plans, providing targeted training, rectifying non-compliance issues, and implementing improved hazard assessment protocols. This comprehensive approach aims to foster a culture of continuous improvement in workplace safety practices.

Hazard Assessment Protocols: Identifying and Mitigating Risks Effectively

Effective hazard assessment protocols are a cornerstone of comprehensive OSHA workplace safety inspections. By systematically identifying potential risks and implementing mitigation strategies, organizations can foster a safer work environment. These protocols involve a detailed examination of each workplace area, job task, and equipment to pinpoint hazards that could lead to accidents or health issues. Once identified, these hazards are categorized based on their severity and likelihood of occurrence, enabling targeted action planning.

Compliance with safety data sheet (SDS) requirements is a critical aspect of this process. SDS provide essential information about the properties, risks, and safe handling procedures associated with chemicals used in the workplace. Integrating hazard assessment protocols into regular OSHA inspections ensures that any discrepancies or non-compliance issues are promptly addressed, enhancing overall workplace safety and adherence to regulatory standards.

Safety Data Sheet (SDS) Compliance: Ensuring Proper Communication of Hazards

During OSHA workplace safety inspections, one critical area that often comes under scrutiny is Safety Data Sheet (SDS) compliance. SDS provide essential information about the hazards associated with chemical products, and their proper communication is vital for ensuring worker safety. During audits, inspectors look for up-to-date SDS that are easily accessible to all employees who might handle or be exposed to these chemicals.

Non-compliance with SDS requirements can lead to serious consequences, including regulatory fines and, more importantly, potential safety hazards. To maintain compliance, organizations must implement robust hazard assessment protocols. This involves regularly reviewing and updating chemical inventories, ensuring that each substance is accurately classified, and providing comprehensive training to employees on the proper handling and emergency response procedures related to these chemicals. Effective communication of SDS information fosters a culture of workplace safety, empowering employees to make informed decisions to protect themselves and their colleagues.

Crafting Effective Audit Follow-Up Action Plans: Strategies for Continuous Improvement

Crafting effective audit follow-up action plans is paramount for organizations aiming to enhance their OSHA workplace safety inspections and hazard assessment protocols. These plans should go beyond mere documentation; they must be strategic roadmaps that address identified nonconformities directly. A well-structured plan starts with a thorough review of inspection findings, ensuring every observed hazard or violation is accurately documented and prioritized based on severity and potential impact.

To facilitate continuous improvement, these action plans should incorporate specific, measurable goals aligned with improved safety data sheet (SDS) compliance. This involves training employees on updated procedures, implementing new controls to mitigate risks, and establishing robust monitoring mechanisms to verify ongoing adherence to enhanced protocols. Regular review meetings and progress tracking are essential components that ensure the plan remains dynamic, adaptable, and focused on preventing future violations, fostering a culture of proactive workplace safety.

Best Practices for Implementing and Monitoring Follow-Up Actions

When implementing and monitoring audit follow-up actions, adherence to best practices is essential for effective workplace safety improvement. One key practice is establishing a clear and structured plan that aligns with OSHA workplace safety inspections guidelines. This involves identifying specific action items stemming from the inspection findings, assigning responsibilities, and setting realistic deadlines. A robust system for tracking progress should be in place, utilizing digital tools or manual checks to ensure compliance with hazard assessment protocols. Regular reviews of the follow-up actions can help identify any gaps or areas that require additional attention.

Furthermore, maintaining meticulous records is vital. Documentation should include details about each action item’s status, the responsible party, and any relevant communication. This comprehensive record-keeping facilitates effective monitoring, enables quick issue resolution, and promotes continuous improvement in safety data sheet compliance. Regularly comparing inspection findings from previous audits against current data sheets helps identify trends and ensures that hazard assessments remain up-to-date and accurate.